Why is your necklace breaking? You have all of the best tools and beading supplies in your beading toolkit, but your designs are coming back from your customers broken. What is going on? What is the best beading wire? What is the difference between Soft Flex wire and other beading threads? Will this seed bead fit on my wire? Today we answer ten customer queries we found on Amazon and other sites. Let's tackle some of your questions!

Join our mailing list:

You may have started designing jewelry twenty years ago. Or maybe you fast tracked and have only been selling your jewelry designs for a couple of years. Chances are, you have some questions. Even the best designers run aground occasionally. Let's navigate some of the issues you face and see if we can answer your questions.

Before we jump into your top 10 questions, we want to be sure that you have had a chance to try our beading wire. One of the biggest problems that designers face (which we talk about later in this article) is jewelry breaking. A great starting point for trouble-shooting breakage is to make sure that you are using a good quality wire in the right diameter.

Email us for FREE samples of our beading wire at Info@SoftFlexCompany.com. We are happy to help you find just the right size, color and length for your next project.

And, if you are a registered jewelry-making business, reselling your designs, you will qualify for special discounts!

Visit our Designer page for more information - Wholesale Beads and Jewelry-Making Supplies for Designers.

Purchase an Assortment of Products from our online catalog and receive the following discounts:

20% off up to $249

30% off $250-$349

40% off $350+

Free shipping on orders over $50 shipping to a U.S. location. No tax.

10 Questions Jewelry Designers Ask About Jewelry Making

Can I Use A Magical Crimper With 2x3 Crimps?

If you design jewelry for a living, chances are, you love trying new techniques and exploring ways to make your jewelry innovative and unique. Adding new tools to your beading supplies is one way to expand your skill set.

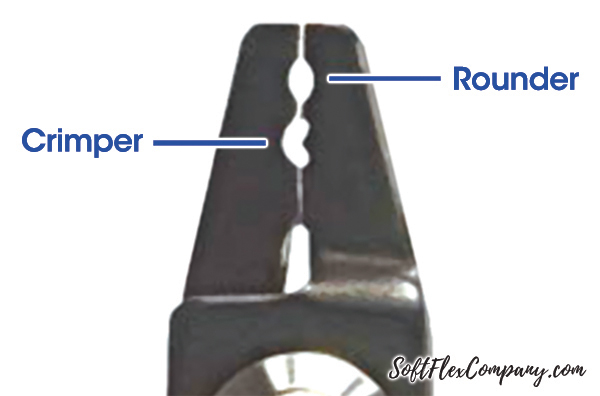

Magical Crimping Pliers are a nice twist on an old tool.

Regular crimping pliers turn a crimp tube into a folded bead. A lot of designers will then hide these folded crimps inside a crimp cover to conceal it.

Magical Crimping Pliers turn a crimp tube into a rounded bead. This bead has the same finish and aesthetic as a crimp cover. This is a great tool for eliminating the process of adding crimp covers if you do not like how regular crimping pliers finish a crimp tube. Even if you do like the look of crimps finished with regular crimping pliers, Magical Crimping Pliers are still a fun tool to have in your toolkit.

Magical Crimpers were designed to be used with 2x2mm crimp tubes. This size conforms to the crimping hole on the pliers. The hole will round the tubes into a bead. 1x1mm crimps are too small for the tool. 2x3mm are too long. If you try to crimp a 2x3mm tube, it is not going to fit in the hole. The good news is that 2x2mm are the most common crimp tubes. So, this is a wonderful tool to add to your collection.

If you need help getting started with your newest tool, we have lot of great instructional videos on our YouTube page and we have a quick guide here - 5 Step Crimping Instructions using the Magical Crimping Pliers.

A Soft Flex Employee Told Me I Do Not Need To Double Back Through Beads, Why?

It is easy to get set in old ways and thoughts when you have been doing something for years. One of the most common rules about finishing a jewelry design was that you needed to double back through the last bead after putting your wire through a crimp tube. This would be a little extra security in case your crimp slipped or broke. This sounds like a wonderful way to ensure your piece doesn't end up with scattered beads on the floor.

But, here is the problem, if you use a wire that fits through your last bead twice, you are using a wire that might be too fine for your jewelry piece. At Soft Flex Company, we suggest using the largest wire that will fit through your beads once. This guarantees your jewelry will be strong and durable. If you use a finer wire, just for a little extra security at the crimp, you are sacrificing the strength of your design as a whole. If you are comfortable with your crimping, you probably do not need to worry about it slipping or breaking in the first place. Use high quality crimps. If you are not using high quality crimps, you are going to have issues with broken jewelry. Don't double back. Use the thickest wire that will fit through the beads once. Cut the wire at the crimp. Your jewelry will be strong and amazing.

If you want basic instructions, click here - Basic Crimping Instructions.

This video has pointers and easy to follow instruction on how we finish our crimps.

Will This Wire Work For Size 15/0 Seed Beads?

Soft Flex Employees, Sara and Kristen, co-authored a book all about seed beads. Unfortunately, it has sold out on our site, but you can still find copies on other sites, like Amazon. Inside, they explored seed bead jewelry. They added loads of information about how to string jewelry using seed beads and Soft Flex. Definitely worth a buy if you love seed beads.

If you just want a quick reference for what size seed beads fit on what size wire, look no further. This handy reference will answer all of your questions with a glance. We adore seed beads. Share your finished jewelry with us on our Facebook group – VIB.

Very Fine .010 Diameter

4 strands through a size 15° seed bead

8 strands through a size 11° seed bead

16 strands through a size 8° seed bead

23 strands through a size 6° seed bead

Fine .014 Diameter

2 strands through a size 15° seed bead

2 strands through a size 11° seed bead

6 strands through a size 8° seed bead

8 strands through a size 6° seed bead

Medium .019 Diameter

1 strand through a size 15° seed bead

1 strand through a size 11° seed bead

4 strands through a size 8° seed bead

5 strands through a size 6° seed bead

Heavy .024 Diameter

0 strands through a size 15° seed bead

1 strand through a size 11° seed bead

2 strands through a size 8° seed bead

4 strands through a size 6° seed bead

Can I Use 2x2 Crimps With Your Heavy Diameter?

2x2mm crimps are definitely the most commonly used crimp tubes in our jewelry. They fit our .014 Fine and .019 Medium wires perfectly. They will keep everything secure and they look amazing when finished. We have a 2x3mm crimp we suggest for our .024 Heavy diameter. 2x2mm crimps work with Heavy just fine, but we figured a little extra length would really keep the Heavy diameter at bay.

2x3mm adds just a slightly longer length to the crimp tube. This means a little more surface area is covering your wire and keeping it in place. Since our Heavy diameter is a thicker wire, we feel that having a longer crimp is going to reinforce the security. However, 2x2mm crimps do work wonderfully. This is a subjective design element, honestly. If you are a crimping pro, you can finish just fine with a 2x2mm on Heavy wire. If you are just starting out or are not quite comfortable with your finish, 2x3mm is going to take the worry out of your finished ends. Go with your gut instinct on this one.

Is This Silver Wire? What Does It Look Like Naked? Can I Melt It Down?

Soft Flex Extreme is one of our favorite brands. This wire is lush and gorgeous. It is meant to be shown. Extreme is perfect for high end clients or designs that demand red carpet perfection. We offer three types of wire in our Extreme Flex collection: 24k Gold, 925 Sterling Silver, and Champagne. This wire is a perfect way to showcase your AAA gemstones.

Some common questions we field, regarding this wire: how is it constructed, can it be melted down, and can the nylon coating be stripped from it?

Extreme Flex Wire is a copper alloy beading wire constructed of 1x19 micro woven wires. Each wire is plated with metal. It is not a solid 24k Gold or 925 Sterling Silver. It is plated metal. Trying to melt our wire down is a terrible idea. We wanted to create a wire that was strong and had the elegance of precious metals. We think keeping the wire intact is the best idea. We don't really suggest removing the nylon coating either. This wire was designed to be a premium beading wire. Please don't dismantle it.

We love our Extreme wire. We are also proud that it was the first green beading wire on the market. Everything about Extreme is recyclable and friendly to the environment. No heavy metals were used in its construction. You can recycle everything from the wire to the spool. You can be eco-friendly and still be a premium designer. Like other Soft Flex brands, this wire is strong and it is supple enough that you can knot it.

Why Do My Customer's Necklaces Keep Breaking?

Whether you are designing for yourself or your eager customers, there is nothing worse than creating a piece of jewelry that is prone to breaking. You have some wonderful tools, you use the best wire, but you are still dealing with broken jewelry. What in the world is going on?!?

Well. It could be a number of things. Fortunately, they are all easy to troubleshoot. You can course correct and fix your issues very easily.

Crimps are likely a culprit. Are you using durable crimps? You can find some real stinkers out there. Some are poorly constructed or made with a hard base metal. Some crimps are closed with a seam, which can weaken them. Some crimps are painfully skinny and could use a little extra bulk. Make sure you are spending a little extra on your crimps. Don't settle for second best. Restringing a broken design is never fun.

At Soft Flex Company, we sell crimps made of softer metals - copper, sterling silver, and gold filled. These metals are easily crimped and conform around the wire. Our crimps are double wall thick - much thicker than most on the market, they are equipped to withstand the most abrasive jewelry owners. Our crimps are seamless, there are no weak points in this amazing crimp. You can be confident with your designs.

Ok, you bought Soft Flex Crimp Tubes - and somehow that broke, what is this madness?!?

If you have an issue with our high quality crimps, we need to look at your tools. Are you using crimping pliers or just smashing your crimps down with a pair of regular pliers? We strongly suggest using crimping pliers to finish your crimps - the right tool for the right job! If you just smash your crimps, you will end up with a wonky crimp with irregular surfaces. The jagged surfaces of a smashed crimp can cut and abrade skin and beading wire. A smashed crimp is not conforming around the wire and keeping it secure. It will slip, one day or a year from now - are you feeling lucky?

Are you using the right size crimping pliers? We suggest these crimping pliers for these size crimps:

- 1x1mm - Micro Crimping Pliers

- 2x2mm - Regular Crimping Pliers or Magical Crimping Pliers

- 2x3mm - Regular Crimping Pliers

- 3x3mm - Mighty Crimping Pliers

- 3x4mm - Mighty Crimping Pliers

- 3x5mm - Mighty Crimping Pliers

What in the blue blazes! You have Soft Flex Crimp Tubes, you have a pair of crimping pliers, you are using the correct tool for the crimp. But you still have crimps that are slipping or breaking. What is going on here?!?

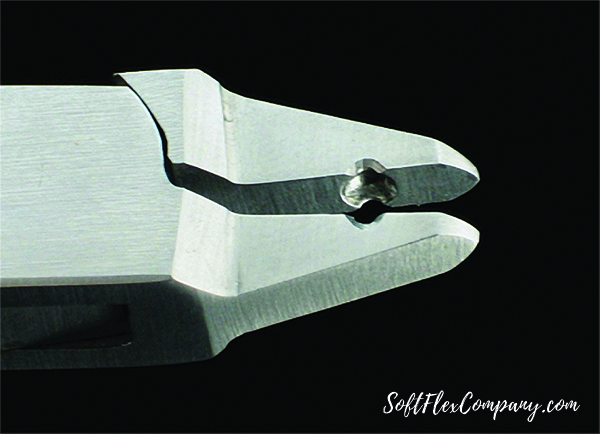

Well, at this point, we need to look at your technique. This blog will answer a lot of questions: How To Use Crimp Beads. Let's look at what you are doing wrong. First, you need to make sure you wire is running parallel inside the crimp. If the wire is criss-crossed, the finished crimp will slip. Put a divot in the crimp tube with your crimping hole. Make sure you put your divot in the crimp so it cleanly separates the two wires. Now round the wire with the rounding hole. We suggest turning the crimp a little each time you crimp down with the rounding hole. So, crimp, rotate your crimp, crimp again - repeat four or five times. Now, you have a lovely finish and a very secure crimp bead.

At this point, your crimp should no longer be slipping. But is it still breaking? If you are using high quality crimps and tools and still experiencing breakage, it is probably how strongly your are crimping down on your tubes. You do not need to CRUSH your crimp tubes. You are going to work harden the metal and make them brittle if you try to smash down with all of your might. We suggest as much pressure on the crimping tool as you would exert shaking your grandmother's hand. Crimp with that pressure, rotate the crimp, repeat several times. Your crimp is not going anywhere. And it will not be brittle.

So. We have mastered our crimping technique. We use the finest tools and crimps. Everything is perfect. But, you are still breaking your jewelry. How are we going to get over this mountain? The last thing we need to check is how your necklaces breath and the diameters of beading wire you are using.

If you like to cover every inch of your beading wire with beads and then crimp as close to the last bead as possible, you are not allowing your design any breathing room. The whole piece is going to be tight and there will be a good deal of pressure on your wire. The stress of this is eventually going to cause your jewelry to snap. Leave some room at the last crimp. Your beads should have a little wiggle. If you are concerned about your beading wire showing, get a color wire that complements the design so it actually works with your beads and does not distract from the piece.

Show your colors!

Make sure your beads do not have obstructions in the channels. If you are having bad luck with a particular set of beads breaking your jewelry - it is possible the inside of the hole has irregular surfaces that grind into the wire as the jewelry is worn. This constant tearing can wreck any beading thread or wire. If you use a bead reamer to clean out the inside of problematic beads, you will spare yourself many headaches.

Finally. Make sure you have the correct diameter for the job. If you are using a smaller diameter than recommended for a project, you may have issues with that wire. Here is a handy reference:

.010 Very Fine - Ideal for embellishing, weaving, crocheting and stringing very small beads. We suggest finishing with 1x1mm crimps.

.014 Fine - Ideal for soft materials, seed beads and fresh water pearls. We suggest finishing with 2x2mm crimps.

.019 Medium - Ideal all purpose wire. Great with glass, mineral, and metal beads. We suggest finishing with 2x2mm crimps.

.024 Heavy - Ideal for abrasive materials, large stones, lamp work and bracelets. We suggest finishing with 2x3mm crimps.

Could I Knot This Thread Easily? I'm Looking To Replicate The Knots Usually Found Between Pearls.

Traditional pearl necklaces are wonderful. Simple, elegant, amazing. A pearl framed between knotted silk looks elegant and timeless. Can this look be made with Soft Flex wire? Well. Yes and no. All of our wire diameters are knottable and supremely flexible. But, knotting between pearls is not going to have the same look and drape. If you want that classic look, we would suggest sticking with silk.

That said, our wire is fantastic for knotting or braiding. Don't count us out. All of our diameters look amazing in knitted. designs All of our diameters are fantastic for kumihimo braids. And you will fall in love with knotted macrame Soft Flex jewelry. There are plenty of applications for Soft Flex and Soft Touch Beading Wire - weaving, stitching, embellishing, working on a loom, and stringing beads.

Yes, you can use our beading wire for pearls, we suggest our .014 Fine diameter, but we want you to expect a different look than the traditional pearl necklace.

Do I Need To Pre-Stretch Beading Wire?

There is a common misconception that beading wire stretches when used for necklaces and bracelets. Soft Flex Wire is comprised of woven strands of stainless steel coated in nylon. It is not the stainless steel that has stretched, so what is it? When a design appears to have stretched and there is more room between the crimp and the final bead than was originally intended, the strands of steel in the braid have pulled tight. This usually only happens when you are using too thin of a diameter for the type of beads or design that you are stringing or if you pull a design too tight when crimping.

There are lots of remedies to pre-stretch the wire to avoid this, but the easiest way is to just use the correct diameter of wire for whatever project you are designing.

Click here to learn about which diameters to use for your project.

To work proactively, string your beads onto the wire. Attach a

Bead Stopper on each end of the design and thumbtack the design to the wall, safety pin to a curtain or hang from a door knob. Allow the design to hang for a few days. The weight of the beads should tighten down the woven stainless steel braid, and then you can attach your clasp. Remember to leave a bit of room between your last bead and the final crimp. Don't pull it too tight.

Will This Wire Corrode And Break From Being Worn 24-7 (While Sleeping And Showering)?

Soft Flex wire is constructed out of marine quality stainless steel. It is designed to last. It is designed to be worn. It is designed to weather the storm. Soft Flex is also nylon coated. Our wire is not going to rust or turn ugly on you. Soft Flex is kink resistant. Your jewelry is going to look amazing. But, don't sleep in it. That is no way to treat your jewelry.

Soft Flex is a kink resistant steel wire. But like any steel wire, it will kink if you force a kink into it. Treat your jewelry nicely and your designs will last for years. Our show demo jewelry has traveled with us around the States, and sometimes around the world. After decades of shows, it is astounding how well our necklaces withstand the stress of being packed into totes and handled by strangers, year after year. Illusion jewelry, single strand necklaces, earrings - they have all be pulled, tugged, and worn and all look amazing. You are going to love how it feels to design with confidence!

What Is The Difference Between Soft Flex Beading Wire And '____' Brand Beading Wire?

Finally, we answer the question that is probably asked the most.

What is the difference between our beading wire and Company X's beading string?

Well, we have an answer for you. We don't know. We don't use other beading wires. Most of us at this company have been here for decades and love our product. There is no need to explore others. So, that is a subjective question. You may find our wire has the most perfect drape, the best look, the most interesting colors. Or, you might enjoy Company X's latest beading thread. Their wire may feel just a little better to you.

We always suggest that it is best if the wire does the talking. Go to a bead store or contact a wire manufacturer. Ask for a sample or buy a small spool. Use your senses to judge. Do you love how this wire drapes? Isn't this flexibility gorgeous? You know what you like best. Don't let somebody try to sway you with words. A great beading wire is very easy to discern when you have it in your hands. Poor quality wire will be stiff and uninteresting. High end wire has flexibility, has a silken drape, it can be knotted, and most of all, it is pleasing to hold and use in jewelry.

Email us for FREE samples of our beading wire at Info@SoftFlexCompany.com

Let the wire do the talking.

Visit our Designer page for more information - Wholesale Beads and Jewelry-Making Supplies for Designers.

We hope we answered some of your personal questions. If you ever need assistance, you can call us on our toll free line - (866) 925-3539 - or email at info@softflexcompany.com and we will help you out! We are company that feels it is important to educate and learn from our customers. You can connect with us on our social media and join our Facebook group if you would love more deep dives into jewelry making.

Join our Facebook group – VIB. Stay in the know. Stay up to date. From our bead shows to our video shows and sales, you can stay in touch with us. The community is full of artistic and helpful beaders and crafty people. Inspire and be inspired. Share your pictures and get the beading bug from others!

Visit the

Soft Flex Company YouTube Channel!

Blog contributor Thomas Soles loves Jazz Age writers and crunchy french fries. His favorite gemstones are Lapis and Pietersite. His favorite hobby is day dreaming. And his favorite mustache is Freddie Mercury's. As you can see, he has a healthy (or possibly unhealthy) sense of humor. You can write to him at Thomas@SoftFlexCompany.com